Research-science

Antimicrobial copper

Over 7 million people are affected globally by healthcare associated infections each year – MRSA, E-Coli, Coronavirus to name a few. 37,000 people die due to these infections annually in Europe and over 100,000 in the US. 80% of all infections are spread by touch and one contaminated hand will go on to contaminate at least 7 other touch surfaces on average.

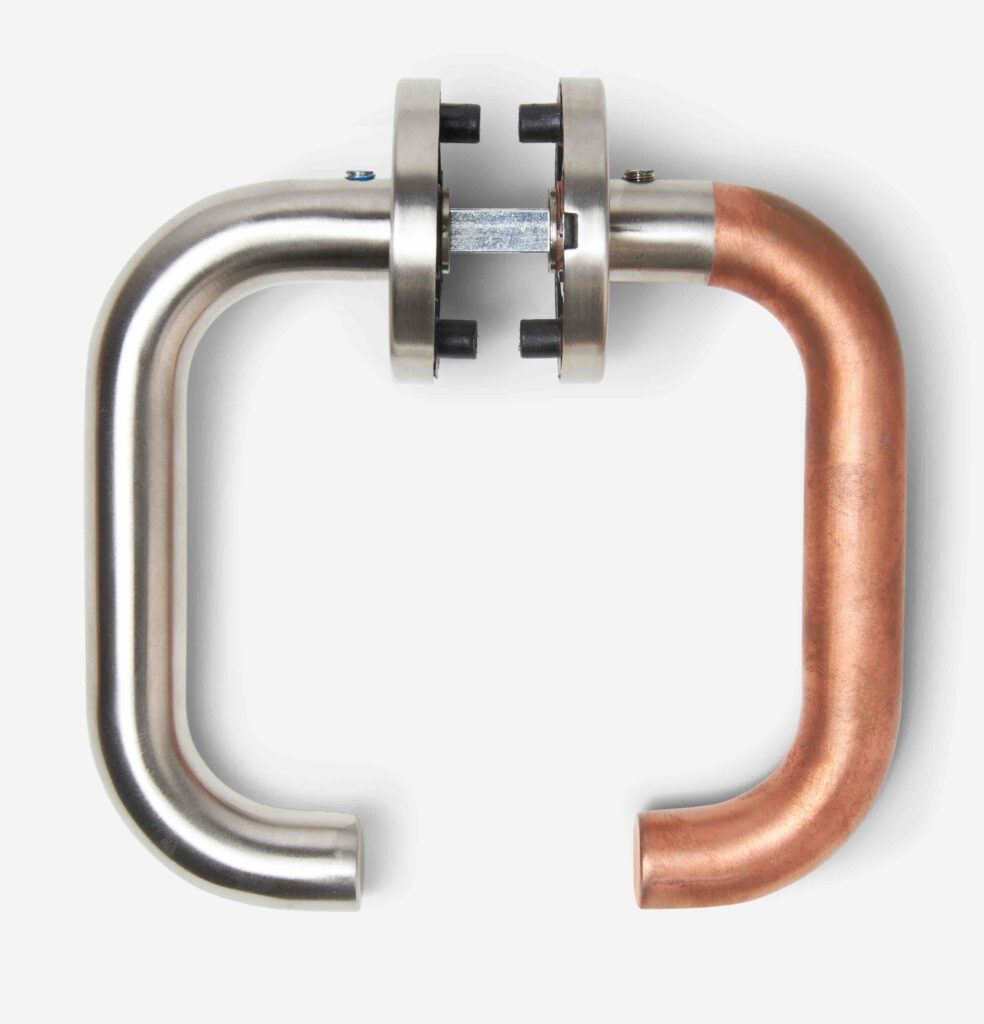

The material of the touch surface makes a vital difference. Harmful bugs can survive on stainless steel and plastics for days, if not weeks or months. With copper, they die within minutes as it shuts down the cells biochemistry and physiology. That is why quite a number of hospitals around the world have begun to make the changeover to copper touch surfaces. But the spreading of infections in other environments such as schools, universities, offices and government buildings can also take place. This results in sickness absence and increasing absenteeism. With Copper-Cover, the spreading can also be stopped now.

Evidence effectiveness of Copper-Cover

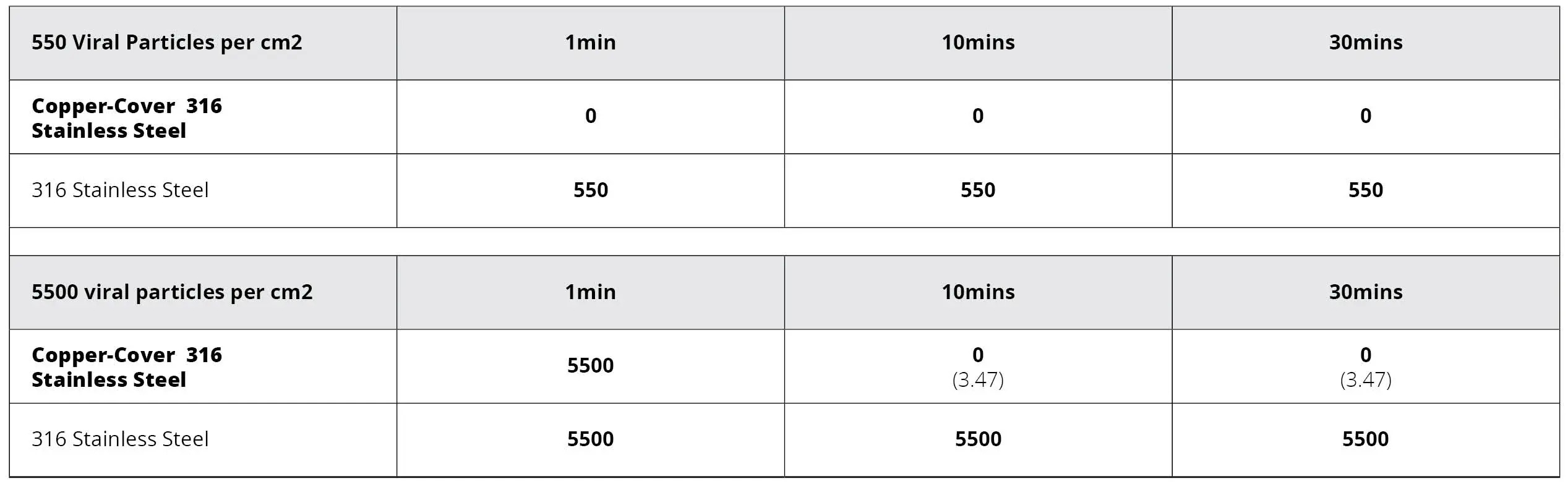

Recent research from the Research University in Southampton has shown that Copper-Covers can kill/inactivate 550 viral particles per cm2 sample of SARS CoV 2 within 1 minute. The test compared the effectiveness of copper-clad 316 stainless steel to normal 316 stainless steel surfaces in killing/inactivating Covid-19.

550 virus particles per cm2 corresponds to a standard hand transmission of Covid-19 and 5500 virus particles per cm2 is the equivalent of a drop of moisture with Covid-19. The results are as follows:

Antimicrobial Copper Surfaces for the Reduction of Health Care–Associated Infections in Intensive Care Settings

Summary:

Health care–associated infections (HAIs) are infections that are caused by a wide variety of bacteria, fungi, and viruses during the course of receiving medical treatment or surgical procedures in a health care facility. Bacterial contamination on various surfaces in the patient’s environment, such as door handles, tables, intravenous (IV) poles, bed rails, or sinks, can be a source of transmission. Pathogens that cause HAIs — including methicillin-resistant Staphylococcus aureus (MRSA), Acinetobacter spp., vancomycin-resistant Enterococcus spp. (VRE), and norovirus — can survive on environmental surfaces for days to weeks. Clostridium difficile (CDI) spores may survive on surfaces for months. Treating HAIs has become more difficult as antimicrobial resistance has increased and the number of effective antibiotics has declined. More than 50% of HAIs are caused by bacteria that are resistant to at least one type of antibiotic. However, fewer pharmaceutical companies are developing new antibiotics. The US FDA has approved only two new antibiotics in the past five years — an 88% decrease from the mid-1980s.

Read more below

Regular surfaces made of plastic, stainless steel, coated metal, and wood are quickly re-contaminated after cleaning. Studies have shown that fewer than 50% of hospital room surfaces are adequately cleaned when standard chemical disinfectants are used. Similarly, inadequate cleaning of portable medical equipment has also been demonstrated. There is evidence that the risk of hand or glove contamination with antibiotic-resistant organisms is high after contact with the surfaces in a patient’s environment. Furthermore, a lower compliance with hand hygiene has been observed when health care professionals have contact with the patient’s environment but not with the patient. Hence, despite efforts to promote infection control practices, HAIs are a common complication of hospital care, resulting in prolonged hospitalization, higher readmission rates, and increased mortality. An estimated 10% of adults in Canadian hospitals have an HAI at any given time. One in every 12patients in Canadian hospitals are colonized or infected by CDI, MRSA, or VRE ― the antibiotic-resistant organisms that currently pose the biggest challenge to Canadian health institutions. In Alberta, the Department of Health estimates that the cost of caring for a patient with an HAI ranges from $2,000 to $20,000.

The Technology:

Surfaces made of copper and copper alloys offer a new approach for reducing bacterial contamination, transmission, and rates of HAIs. Metallic copper has been shown to have intrinsic and continuous broad-spectrum antimicrobial activity. While using pure copper results in the fastest killing of pathogens, many of its alloys consisting of at least 60% copper (including brasses and bronzes) are also effective and offer a range of enhanced properties, such as strength, durability, several colours, and tarnish resistance. Collectively termed “antimicrobial copper,” surfaces manufactured from copper and its alloys are intended to provide supplemental antimicrobial action between periods of routine cleaning of environmental or touch surfaces. Most standard hospital detergents and disinfectants will not affect the efficacy of antimicrobial copper, with the exception of products containing metal ion chelators, such as ethylenediaminetetraacetic acid (EDTA).

Laboratory tests show that antimicrobial copper surfaces kill 99.9% of specific infectious bacteria (including S. aureus, Enterobacter aerogenes, Escherichia coli O157:H7, Pseudomonas aeruginosa, MRSA, and VRE) within two hours or less and continuously kill more than 99% of bacteria even after repeated contamination. Additional data suggest copper might also be effective against other bacteria, viruses, and fungal pathogens. Although the mechanism of action has not been confirmed, it is postulated that the toxicity of copper involves the rupture of the cell membrane, the generation of reactive oxygen species, and the breakdown of bacterial DNA, resulting in cell death. Due to this multi-targeted mode of action and the rapid degradation of bacterial DNA, the development of copper resistance and the spread of antibiotic-resistant organisms is considered unlikely. Copper’s antimicrobial properties are expected to remain in effect for the product’s lifetime, as they do not rely on coatings or impregnated surfaces that can wear off or wash away. Some natural tarnishing may take place, depending on the alloy, but this does not appear to affect efficacy.

Antimicrobial copper can be incorporated into a wide variety of components, including bed rails, overbed tables, door handles, IV poles, lavatory components, and work surfaces. Antimicrobial copper products are available from both primary manufacturers and stockists. Globally, there are thousands of suppliers of both raw materials and semi-finished products. CuVerro Bactericidal Copper Surfaces (Olin Brass, GBC Metals, LLC, Louisville, Kentucky) is a leading manufacturer and distributor of antimicrobial copper alloys in North America and one of the largest in the world. Products made with CuVerro Antimicrobial Copper, such as IV poles, tables, and stretcher rails, are available across the US through various manufacturers, including Midbrook Medical (Jackson, Michigan) and Pedigo Products, Inc. (Vancouver, Washington).

We believe in a safe and healthy work/living environment. Contact surfaces play an important role because of the transfer of bacteria and viruses.

The spreading of viruses and bacteria via contact surfaces such as door handles, door handles and bannisters has proven to be a major problem in recent years. 80% of all infections are spread by touch and one contaminated hand will go on to contaminate at least 7 other touch surfaces on average. We stop the spread via touch surfaces. (University of Southampton, Professor Bill Keeble explains the workings and shows the workings of Copper). Many chemical cleaning products are currently used to keep these contact surfaces clean.

Copper Concepts offers an efficient, durable and chemical free solution to stop the spread through contact surfaces. We ensure that your employees and/or guests remain safe and healthy.

With our Copper-Concepts we will:

- Reduce employee absences.

- Secure confidence to come back safely to the office, ministry or school.

- Save costs on cleaning and chemical disinfectants.

- Re-use of door handles, bannisters and pressure plates.